Founded in 1947, ATAG is a solid and important organization serving industry. With three branches in Italy and prestigious Italian and foreign partners, it represents a leading player in the supply of technical products.

ATAG is a hub with a more than 10,000 square meters warehouse and an extensive sales network. It performs in-house processing on rubbers and plastics – from semi-finished to finished products – to contain costs and maximize efficiency and production control; it offers a precision machining for the customization of items but, above all, ATAG guarantees a service based on the qualified technical expertise of its Sales department. ATAG is continually innovating.

This strategy has resulted in a service that caters to all sectors of industry: from food to pharmaceuticals, from medical to the aerospace, electronics and automotive. On this base, and seeking solutions to special high added value applications, our aim is to continue being a hub for industry in all sectors.

ATAG extrudes and molds all kinds of rubbers in house, and produces many varieties of flexible hoses in polyurethane, or technical fabrics on large volumes.

It is able to shape any rubber or plastic materials through various 3- and 5- axis pantographs and water-jet machines, and has recently expanded its equipment with plotters as well.

ATAG, always at the forefront, has redesigned its ecological impact policies by installing a modern photovoltaic system, and has recently updated its software and internal company processes, achieving a better control on details and an overall efficiency. At the same time, its Logistics and Quality departments are in constant renovation to comply with safety regulations.

The most gratifying successes for ATAG in the medical sector in recent times are related to the partnership with Piercan, a well-known manufacturer of gloves and accessories for the protection and non-contamination of humans and processes in drugs formulation or transformation.

ATAG also supplies the pharmaceutical production areas with both polyurethane hoses for handling tablets and capsules.

and rubber hoses with special fluorinated substrates, essentially inert, for the transport of active ingredients for their own production. The hoses can also be coupled with specific connections – mainly Tri-Clamp type – and provided with the required certifications.

ATAG provides the pharma sector with certified compact or expanded silicone gaskets to use in the manufacture of mixers, granulators or kneading machines, but also for dispensing, washing, and loading and compression.

A special ATAG silicone gaskets formulation was used in the production of helmets for COVID-19 patients’ oxygenation.

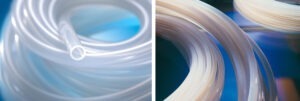

ATAG supplies special platinum silicone tubing for hemodialysis machines’ production, in compliance with the standards: ISO 10993-1 – FDA 21 CFR 177-2600 – USP CLASS VI – EP 3.1.9.

ATAG special flexible polyurethane or FDA silicone sleeves and connectors

also play a key role in production facilities, particularly where powdered excipients are processed, during the discharge phase inside load cells