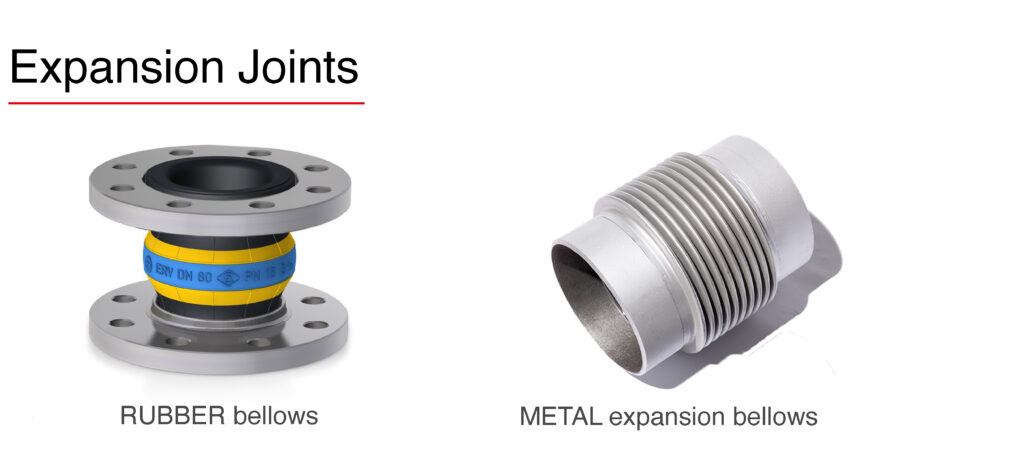

Compensate for expansion and vibration in installations with rigid hoses with the wide range of joints available from ATAG SPA.

For those in industries where hoses is crucial, expansion joints are essential to improve fluid flow.

ATAG’s joints – metal or rubber – meet axial, angular, spherical or universal compensation requirements.

The ideal joint, standard or customised to your individual requirements, will ensure:

- avoid misalignments

- absorb structural/vibrational imbalances

- prevent decoupling points in rigid installations

Whatever your application for these expansion joints, the ATAG SPA Technical Department will advise you on the suitable material.

In fact, ATAG guarantees short delivery times throughout Italy for the following types of joint:

- rubber joint

- metal joint

Let’s discover together the characteristics of the two main types of joint.

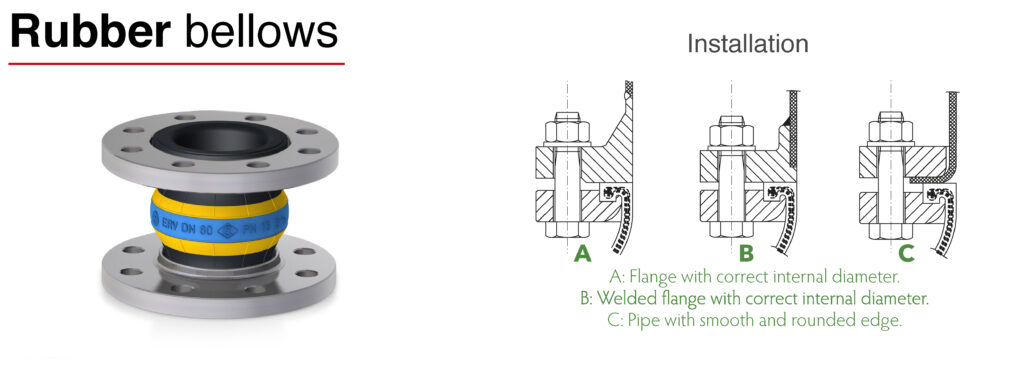

Made of EPDM, Nitrile, Hypalon®, Neoprene, etc., these joints are used in a variety of industrial and naval applications due to their flexibility that allows axial, lateral and angular movements, thus absorbing both thermal expansion and all mechanical movements. With these joints you will also avoid damage, as they are excellent for absorbing vibrations and shocks and reducing possible impacts with other system components.

ATAG’s engineers also recommend these joints to those working in industries where corrosion and chemical agents are commonplace, because they also adapt to dangerous and aggressive working environments.

Lightweight and very easy to install, they also compensate for large variations in temperature, balancing the expansion and contraction of hoses and preventing leakage of fluids and gases, even under pressure.

Choose them also if you want a quieter and more comfortable working environment and if you need a durable item that helps in the total performance of the whole industrial plant.

Stop the effects caused by changes in temperature and pressure!

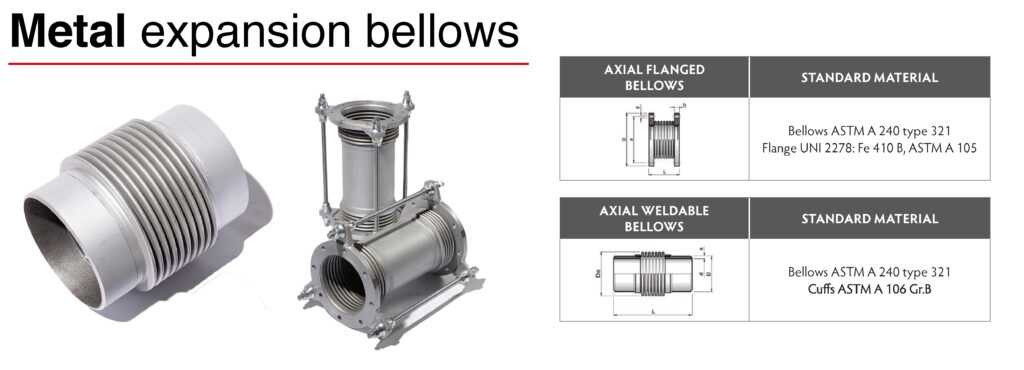

Metal expansion bellows have a metal bellows (made of stainless steel) that absorbs all movements of the hoses in the system to which they are applied.

When pressure values are high, compensate for them with ATAG metal couplings, especially if you are dealing with work requiring large diameter hoses.

Furthermore, metal expansion bellows are not subject to wear and tear; that’s why you choose them!

Why ATAG

By choosing ATAG expansion joints, you can be sure that you are relying on a business partner that has been present in Italy since 1947.

Constantly growing and with a wide range of articles for the industrial sector, ATAG bases its roots on the constant qualified and competent technical advice offered by its sales and technical department, prepared to advise you in the best possible way in every situation!

We boast improved solutions for Italian industry, continuing to innovate with enthusiasm and a desire to surprise.

Don’t wait any longer.

Try ATAG’s technical articles for industry.

View the complete catalogue on EXPANSION JOINTS.